Services

We provide selective electroplating repairs for:

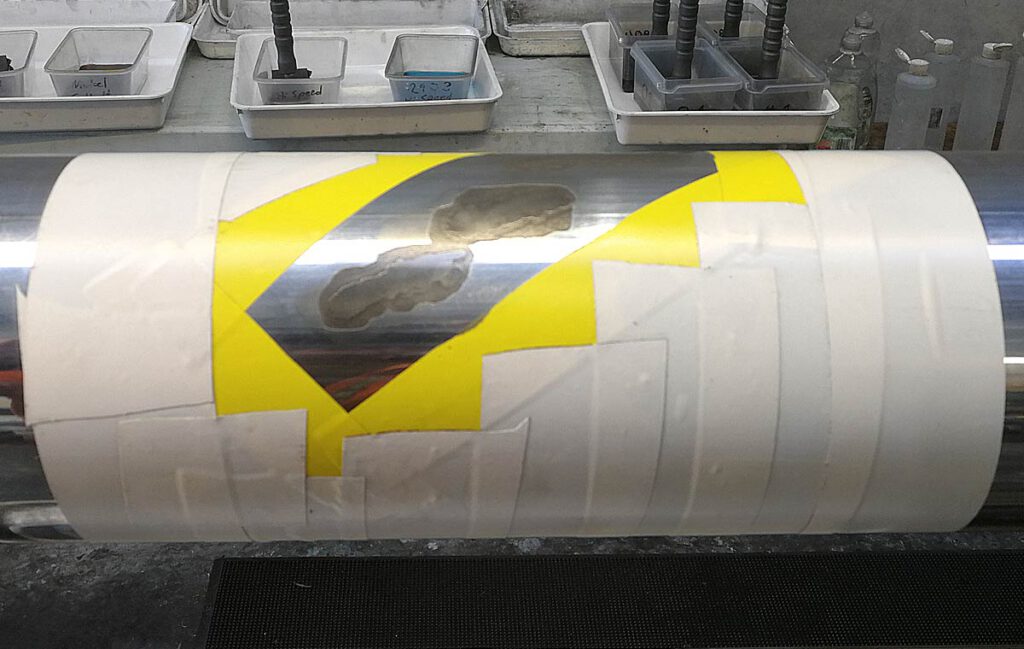

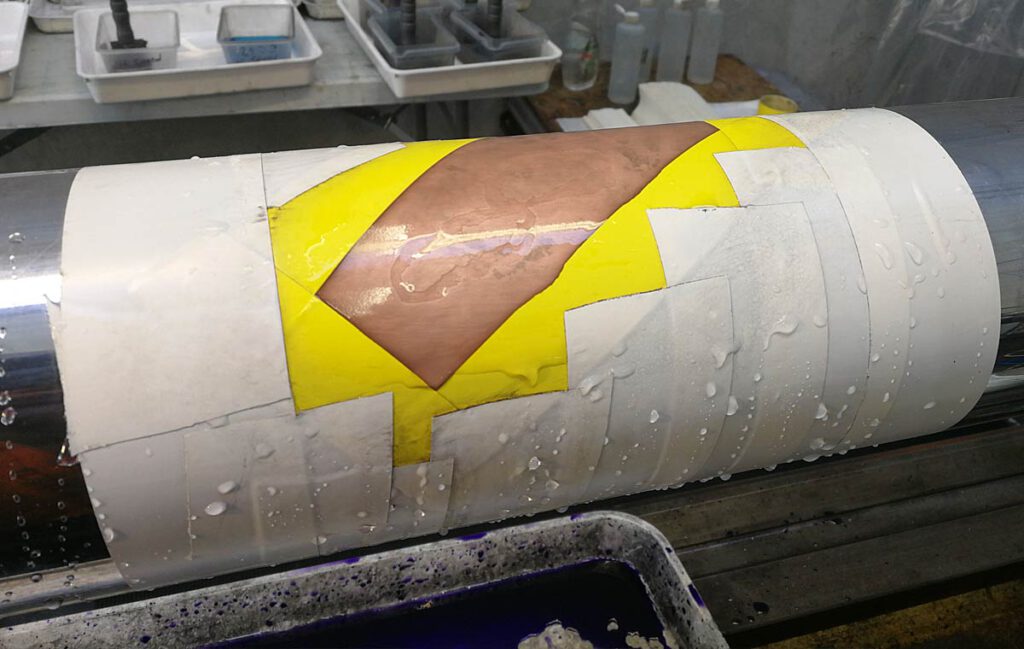

Print Cylinders

Chrome Shafts

Scores & Dings

Shaft Seals

Worn Journals

Corrosion

Hoist Cylinders

Large Parts (in-situ)

Forklift Masts

Steering Shafts

Spear Damage

Suspension Cylinders

Resizing Metal Componentry

Metal components that are out of dimensional tolerance due to wear or corrosion can be restored to original factory dimensions.

Rebuilding Metal Componentry

Metal components that are damaged (dents, gouges, grooves, scratches etc) or machined can be repaired and resized.

Resurfacing Metals

Our process can restore or improve surface properties such as electrical conductivity, corrosion resistance, hardness and wear resistance.

What is Selective Electroplating?

Originally developed in France circa 1938, selective electroplating–or brush plating–is an electrochemical process specifically designed to be a portable and versatile method of electroplating (coating metal components). Brush plating is performed on localised areas and does not require immersing the part in large tanks of chemicals.

Selective electroplating has been used for the repair and for OEM applications over a wide range of industries from offset printing and manufacturing to aviation and marine.